- Home

- >

- News

- >

- Acetylene Gas Plant

- >

Acetylene Gas Plant

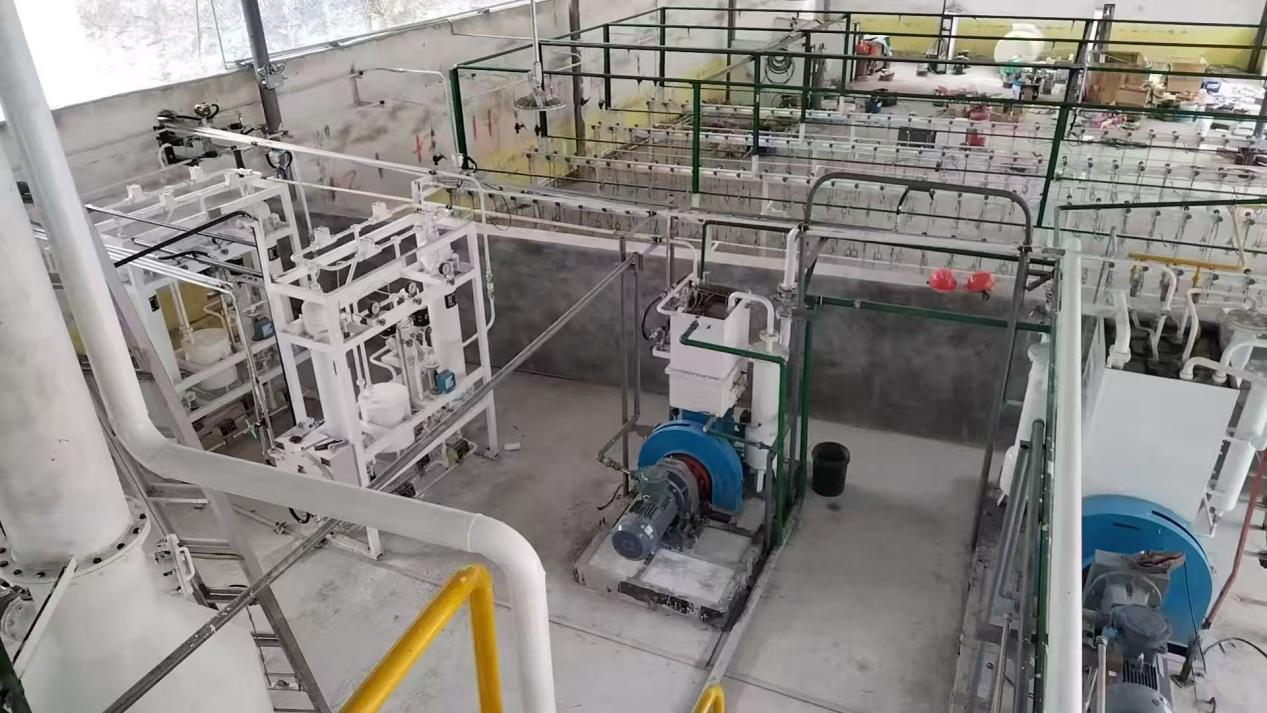

2025-11-24 18:05Below is a set of closed oscillating acetylene production lines manufactured by our company, Liaoning Jinding Technology Development Co., Ltd. The installation has been completed and is now ready for commissioning. The following are on-site installation photos of this closed oscillating acetylene production line for reference by interested buyers.

Acetylene gas piston compressor

Low pressure cooling dust collector Closed type oscillation acetylene generator

Closed type oscillation acetylene generator

Acetylene gas holder

Closed type oscillation acetylene generator ( main generator & sub-generator)

Relevant water piping for acetylene generator

Closed type oscillation acetylene generator ( main generator & sub-generator)

Molecular sieve high pressure dryer & piston compressor

Uses of acetylene gas:

Acetylene (C₂H₂) is a highly reactive and high-calorific-value unsaturated hydrocarbon gas. With its unique chemical and physical properties, it is widely used in industries such as chemical manufacturing and metallurgy. Its core applications focus on three main scenarios: high-temperature processing, chemical synthesis, and specialized energy use, as detailed below:

1. Core Application: Industrial High-Temperature Processing (Most Mainstream Use)

When acetylene burns, it produces a high-temperature flame (oxygen-acetylene flame) ranging from 3000 to 3300°C, serving as a crucial industrial heat source for various metal processing applications

Metal Cutting: Oxygen-Acetylene Cutting (Gas Cutting) is a traditional and versatile metal cutting process. It involves heating steel and other metals to their ignition point with high-temperature flames, then removing molten slag with high-pressure oxygen to achieve rapid cutting. This method is suitable for carbon steel and low-alloy steel workpieces with a thickness of 5mm or more, and is widely used in shipbuilding, bridge construction, steel structure manufacturing, mechanical dismantling, and other applications. It offers high cutting efficiency and portable equipment (especially ideal for field or on-site operations).

Metal welding: Oxygen acetylene welding (gas welding) uses a high-temperature flame to melt the base metal and filler metal, forming a firm joint. Suitable for welding materials such as low-carbon steel, cast iron, copper, and copper alloys, especially suitable for small workpieces, thin-walled parts, or non power scenarios (such as field maintenance, pipeline repair), with low equipment cost and flexible operation.

Metal heating/heat treatment:

Local heating: used for hot assembly of mechanical parts (such as hot fitting of bearings and gears), bending and forming of pipelines, thermal expansion and loosening of bolts, etc;

Heat treatment: Annealing, normalizing, quenching and other processes are carried out on small workpieces to enhance material hardness or toughness (such as quenching tool steel and annealing cast iron parts).

Spray coating: Using the high temperature of an oxygen acetylene flame, metal powder (such as zinc, aluminum, stainless steel powder) or ceramic powder is melted and sprayed onto the surface of the workpiece to form a wear-resistant, corrosion-resistant, and high-temperature resistant coating, which is used to repair worn parts (such as shafts and gears) or improve the surface performance of the workpiece (such as anti-corrosion of chemical equipment).

2. Chemical synthesis raw materials (high value-added applications)

Acetylene is an important organic chemical intermediate that can be synthesized into various key chemical products through addition, polymerization, and other reactions

Vinyl chloride (VCM): Acetylene and hydrogen chloride react with a catalyst (such as mercuric chloride) to produce vinyl chloride, which is further polymerized to obtain polyvinyl chloride (PVC) - one of the most widely used general-purpose plastics in the world, used for manufacturing pipes, sheets, films, cable sheaths, etc.

Vinyl acetate (VAM): Acetylene and acetic acid are catalyzed to synthesize vinyl acetate, which is then polymerized to obtain polyvinyl acetate (PVA). PVA is used in the production of adhesives, coatings, fibers, films, and can also be used to manufacture EVA (ethylene vinyl acetate copolymer).

Acetaldehyde: Acetylene reacts with water under the action of mercury salt catalyst to form acetaldehyde, which is an intermediate for the synthesis of chemical products such as acetic acid, acetic anhydride, butanol, and octanol. It is widely used in industries such as pharmaceuticals, pesticides, and coatings.

Butadiene: Acetylene is dimerized to produce vinyl acetylene, which is then hydrogenated to obtain butadiene - the core raw material for synthetic rubber (such as butadiene rubber and styrene butadiene rubber), used in the manufacture of tires, seals, rubber products, etc.

Other fine chemical products:

Synthesis of acetone and methyl methacrylate (MMA) for the production of organic glass;

Production of acetylene black (high conductivity, high wear resistance carbon black, used for lithium battery electrodes and rubber reinforcing agents);

Synthesize metal alkynes such as silver acetylene and copper acetylene (used for explosives and chemical reagents).

3.Special energy and other uses

Lighting source: When acetylene burns, the flame is bright (with high carbon content and high luminous efficiency). It was originally used for underground lighting in coal mines (acetylene mine lights), navigation lights, signal lights, etc., especially suitable for scenarios without power supply; Although modern technology is gradually being replaced by electric lights, there are still a few applications in outdoor work and emergency lighting.

Welding shielding gas (mixed use): Acetylene mixed with argon, carbon dioxide, etc. can be used as a special welding shielding gas for welding stainless steel and non-ferrous metals, improving weld formation and mechanical properties (such as argon acetylene mixed gas used for copper alloy welding).

Rocket propellant (special scenario): Acetylene mixed with oxygen has high combustion efficiency and thrust. It was used as a propellant for early rocket engines and is still used in small rockets and experimental devices.

Analysis and detection: As a carrier gas or standard gas component of gas chromatography, it is used for the separation and detection of organic compounds in chemical samples.

4.Application precautions

Acetylene is a flammable and explosive gas (with an explosion limit of 2.5% -82%, and excessive concentration in the air can easily cause explosions). Storage and transportation require acetylene cylinders (filled with porous materials and acetone to dissolve acetylene), and exposure to sunlight, impact, or near open flames are strictly prohibited;

During oxygen acetylene operations, it is necessary to strictly control the mixing ratio of oxygen and acetylene (O ₂: C ₂ H ₂ ≈ 1.1-1.3 during cutting, ≈ 1.0-1.1 during welding) to avoid the risk of backfire or explosion;

Some processes in chemical synthesis, such as mercury salt catalysis, have environmental issues and are gradually being replaced by ethylene and natural gas methods. However, acetylene methods still have cost advantages in some areas, such as coal rich regions.

In summary, the use of acetylene ranges from "basic industrial processing" to "high-end chemical synthesis", and it is an indispensable key gas in industrial production, especially in high-temperature processing and the manufacturing of chemical products such as PVC and synthetic rubber, which have an irreplaceable position.