- Home

- >

News

the automatic control can reduce the burden of operators, its basic operation is from the calcium carbide loading to acetylene gas cylinders filling, which the whole process is automatic operation, also some functions can be increased according to the requirements of customers

for acetylene gas generating, there are 2 kinds of operation, manual or automatic, for open type generator, manual operation is often used, for closed type generator, automatic operation is often used.

Liaoning Jinding Technology Development Co., Ltd. is a professional manufacturer which produce acetylene gas equipments, various diaphragm compressor and different kinds of mechanical seal such as metal bellows seal, mechanical seal supporting system, cryogenic bellows seal, hand pump and cyclone separator etc.

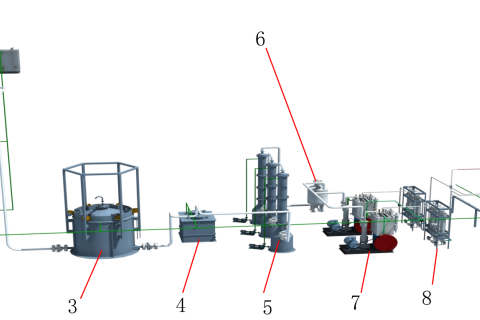

generally, C2H2 production process include C2H2 generating, passing through forward/reverse water seal into C2H2 holder for storage, then entering the low pressure dryer for removing water, pressurized by compressor, entering high pressure dryer for removing water and finally entering C2H2 cylinders filling system.

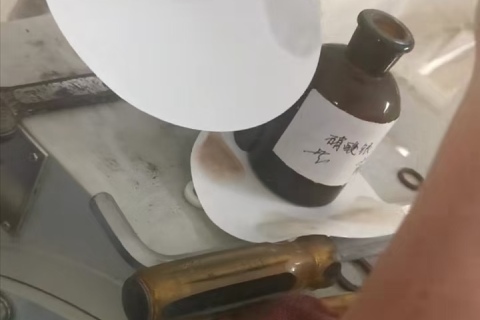

here we introduce a simple method to test the purity of C2H2 gas on site, we dip the silver nitrate solution onto the test paper, then put the test paper under the gas sampler, if the test paper colour doesn't change, the purity of C2H2 gas can reach at least about 98%, this purity is enough to be used in industrial application.

the acetylene gas is compressed by the piston compressor, which is piped to the molecular sieve high pressure dryer, the dryer can remove the moisture, then the dry acetylene gas is piped to the cylinder for filling

acetylene gas is used with oxygen gas for cutting, in order to produce acetylene gas, our factory especially a set of simple production line to produce about98% purity acetylene gas to satify our customers' requirements